Hull liner cut out and support tabbed in. Note the hole cut in the long brace- that is for the drain hose:

Box test fit. Rear outboard corner is cut out to allow for curvature of the hull:

Box installed, lined with fiberglass and painted. The hole is actually a marelon through-hull that was flush fit and glassed over. It leads to an acid resistant hose then to a valve mounted high in the bilge so the box can be drained into a bucket if there is a leak:

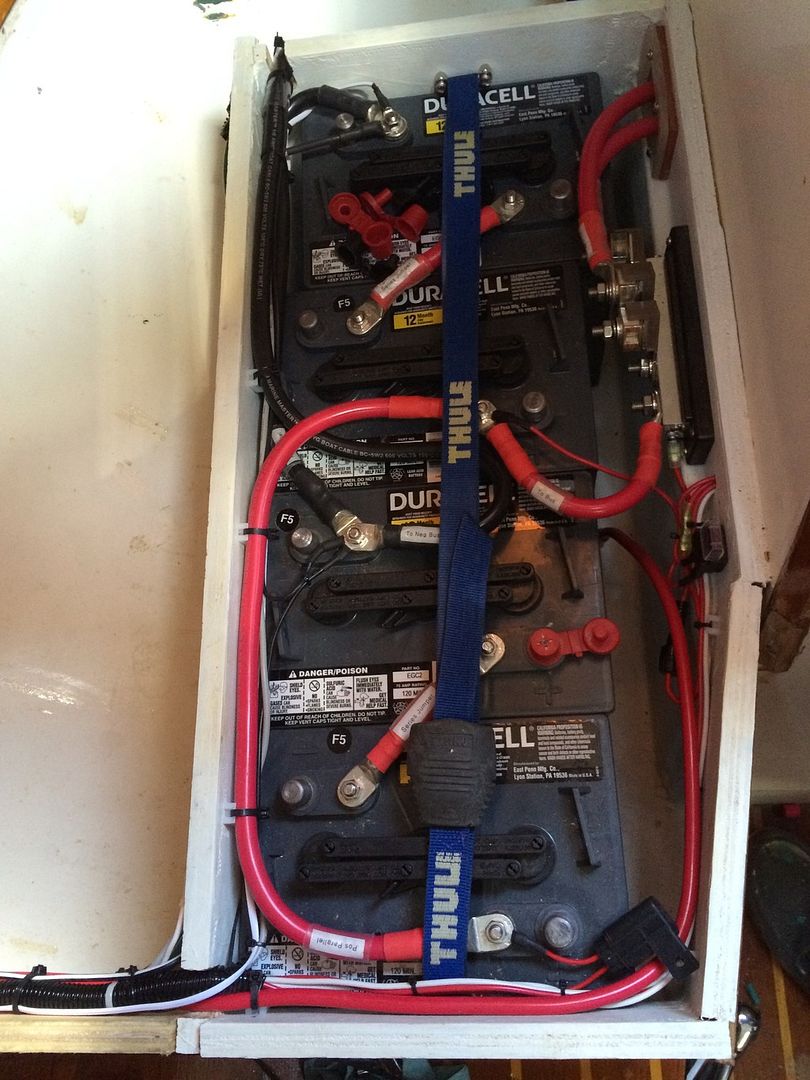

Batteries test fit:

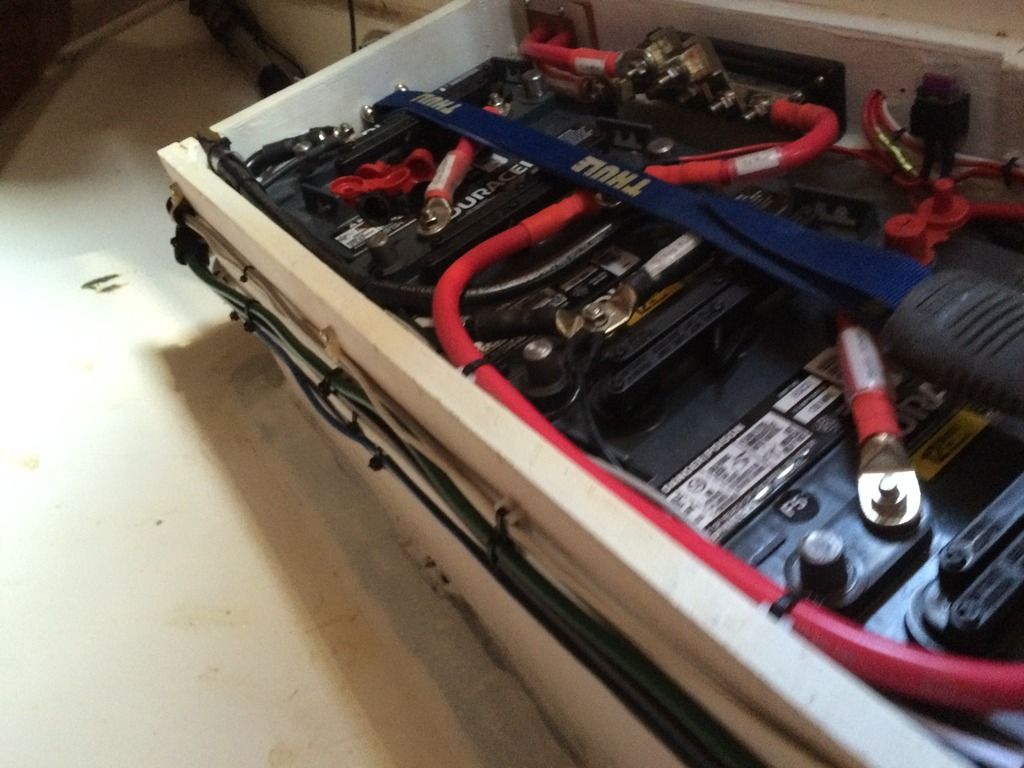

The quarter berth had to be raised 3" to allow for the height of the 6v batteries and to provide a small amount of clearance. The box itself serves as support for the berth at the new height. The rest of the plywood panel had risers attached:

The old access holes aren't in the best location when combined with the new cutout, but the panel is still plenty stiff and doesn't seem to need additional bracing:

Overall, I think we'll be happy with the new bank and the access the new location provides for battery maintenance. There are still a few tasks left to do like make a lexan cover and install a venting system. Wiring the batteries is obviously high on the list. This is a very doable project if you spend some time planning it out. The new height still allows for a comfortable sitting position at the nav station and it doesn't look out of place.

[/URL]

[/URL]