Chainplate Failure! Typhoon Weekender

Moderator: Jim Walsh

Chainplate Failure! Typhoon Weekender

Due to hidden corrosion, the starboard aft chainplate through bolt on my '82 typhoon weekender failed under load in a 20 knot wind with a reef in the main and a working jib hanked on. Fortunately we were able to get the sails down and run bare pole before the whole standing rigging could come down.

I'm now faced with the prospects of having to replace the chainplate and the through bolts. However, I cannot find anywhere to buy replacement chain plates. They seem to be of a design unique to the typhoon.

If anyone know where I can find these chainplates or has a suggestion of an alternative fix in lieu of replacing the chain plates, I would be most appreciative.

Drew A .Smith

CD Typhoon #2012, Original Owner

941-544-6307, Sarasota, FL

I'm now faced with the prospects of having to replace the chainplate and the through bolts. However, I cannot find anywhere to buy replacement chain plates. They seem to be of a design unique to the typhoon.

If anyone know where I can find these chainplates or has a suggestion of an alternative fix in lieu of replacing the chain plates, I would be most appreciative.

Drew A .Smith

CD Typhoon #2012, Original Owner

941-544-6307, Sarasota, FL

Greh3595

-

Carl Thunberg

- Posts: 1327

- Joined: Nov 21st, '05, 08:20

- Location: CD28 Cruiser "Loon" Poorhouse Cove, ME

Custom Fabricated

You're not likely to find stock chainplates anywhere. Your best bet is to remove the one that hasn't failed and bring it to a custom fabricator and have them fabricate two new ones. I think you'll be pleasantly surprised at how inexpensively you can get them made. It's just plate steel with some holes drilled through it. Very little labor involved. There's an endless debate on mild vs. stainless steel, that I won't weigh in on, but if you choose to go with stainless steel this time around, make sure you get marine grade 316 stainless steel. Lesser grades of stainless steel aren't a whole lot better than mild steel.

Also, spend a little time with the search function of this board. You'll find we've kicked around the topic of rusted chainplates quite a bit. Before you get the new ones, though you need to find and fix the leak that rusted the old ones. Rebedding all deck hardware is an excellent place to start.

The good news is, as bad as it seems, you can fix this pretty quickly and get back on the water. In terms of time and effort, this isn't that big a job.

Thank goodness no one was hurt and you were resourceful in getting yourself home! Well done.

Also, spend a little time with the search function of this board. You'll find we've kicked around the topic of rusted chainplates quite a bit. Before you get the new ones, though you need to find and fix the leak that rusted the old ones. Rebedding all deck hardware is an excellent place to start.

The good news is, as bad as it seems, you can fix this pretty quickly and get back on the water. In terms of time and effort, this isn't that big a job.

Thank goodness no one was hurt and you were resourceful in getting yourself home! Well done.

CDSOA Commodore - Member No. 725

"The more I expand the island of my knowledge, the more I expand the shoreline of my wonder"

Sir Isaac Newton

"The more I expand the island of my knowledge, the more I expand the shoreline of my wonder"

Sir Isaac Newton

Carl,

Thanks for your sage advice! Can you point me in the direction of a reputable metal shop that could do the fabrication? The existing chainplates themselves are stainless steel already, and I assume they are 316. What apparently failed was one of the two carriage bolts that through bolt the deck mounted chainplate corroded. Based upon the amount of rust/oxidation I am seeing, it is possible that the bolt itself was not made of a high quality stainless such as you suggest.

I think the biggest problem then with the repair might be getting this rusted, and now snapped off, bolt out of the whole it is in as with the corrosion it has swelled substantially.

Thanks for your sage advice! Can you point me in the direction of a reputable metal shop that could do the fabrication? The existing chainplates themselves are stainless steel already, and I assume they are 316. What apparently failed was one of the two carriage bolts that through bolt the deck mounted chainplate corroded. Based upon the amount of rust/oxidation I am seeing, it is possible that the bolt itself was not made of a high quality stainless such as you suggest.

I think the biggest problem then with the repair might be getting this rusted, and now snapped off, bolt out of the whole it is in as with the corrosion it has swelled substantially.

Greh3595

-

Carl Thunberg

- Posts: 1327

- Joined: Nov 21st, '05, 08:20

- Location: CD28 Cruiser "Loon" Poorhouse Cove, ME

Geez, now I'm confused.

If the bolt's the problem, why do you suspect the stainless steel chainplates? Methinks there's more information to the story, perhaps?

CDSOA Commodore - Member No. 725

"The more I expand the island of my knowledge, the more I expand the shoreline of my wonder"

Sir Isaac Newton

"The more I expand the island of my knowledge, the more I expand the shoreline of my wonder"

Sir Isaac Newton

Getting the bolts out was not a problem. A large hammer and a punch worked fine. After getting the bolts out you should drill the holes over sized. Then place duct tape over the bottom of the hole and pour it full of reinforced epoxy. After the epoxy cures re-drill the holes with the proper size bit. In my case the bolts were 1/4" so I drilled the holes with a 17/64" bit.

My bolts were not carriage bolts; they were machine bolts.

My bolts were not carriage bolts; they were machine bolts.

Have A Nice Day

- Sea Hunt

- Posts: 1310

- Joined: Jan 29th, '06, 23:14

- Location: Former caretaker of 1977 Cape Dory Typhoon Weekender (Hull #1400) "S/V Tadpole"

This is a timely thread for me.

Drew, I admire your skills. If the same had happened to me I very much doubt it would have ended well. I do not have your skills. I read an article in a sailing magazine many, many months ago I think by Ralph Naranjo (spelling ) who had the same thing happen to him on his Ty Weekender. If I recall correctly, he is (or was) a USNA sailing instructor. You have his skills as he was able to bring his Ty under control without further damage.

) who had the same thing happen to him on his Ty Weekender. If I recall correctly, he is (or was) a USNA sailing instructor. You have his skills as he was able to bring his Ty under control without further damage.

On my "to do" list is to check the "chainplates" port and starboard on S/V Tadpole. Initially I had removed the two circular wood cover plates (4" diam) on each side hoping to be able to look up to the chainplates with a small mirror and light. This did not work.

I am now planning on removing the large plastic (fiberglass ) covers on each side that run up each side of the interior of the hull. There are about 8-10 screws in each cover. I am hoping this will give me viewing access to the chainplates.

) covers on each side that run up each side of the interior of the hull. There are about 8-10 screws in each cover. I am hoping this will give me viewing access to the chainplates.

My question is this: Exactly what should I be expecting to be looking at on a 1977 Ty Weekender (Hull #1400) From what I have read, it is my understanding (I am a rookie, so please excuse my lack of detail and probably my lack of accuracy

From what I have read, it is my understanding (I am a rookie, so please excuse my lack of detail and probably my lack of accuracy  ) there should be a large metal plate embedded in fiberglass. The turnbuckles are then connected to these plates with bolts (or screws).

) there should be a large metal plate embedded in fiberglass. The turnbuckles are then connected to these plates with bolts (or screws).

If there is corrosion in these plates (assuming I am correct that they are embedded in fiberglass), what are the physical signs of corrosion that I should expect to see Will rust show through the fiberglass

Will rust show through the fiberglass  Please excuse my lack of knowledge and understanding. It is a steep learning curve for a dummy like me

Please excuse my lack of knowledge and understanding. It is a steep learning curve for a dummy like me

If corrosion is present, what is the procedure for repairing I am "assuming" you must drop the mast, unbuckle the turnbuckles and then cut out or dig out the plates, replace the plates, bolts, etc. and refill with fiberglass. I am also assuming this must be done from the deck digging down into the fiberglass to the plate(s) versus digging out the rusted plate(s) from below. This would mean redoing the deck in that area as well. Am I close

I am "assuming" you must drop the mast, unbuckle the turnbuckles and then cut out or dig out the plates, replace the plates, bolts, etc. and refill with fiberglass. I am also assuming this must be done from the deck digging down into the fiberglass to the plate(s) versus digging out the rusted plate(s) from below. This would mean redoing the deck in that area as well. Am I close

OJ, I could really use your help on this

The good news, if it is good news, is that there does not appear to be anything readily observable that looks like rust, corrosion, etc. On deck, the plates that are fastened to the deck appear to be without any rust or corrosion. The turnbuckles themselves also appear to be without rust or corrosion. In the cabin I do not see any observable rust or corrosion trails, etc. but I have not yet opened up or removed the large plastic panels.

Any and all help is much appreciated. Please remember I am a dummy. Instructions, suggestions, etc. should be kept simple. Pictures and diagrams would help.

Instructions, suggestions, etc. should be kept simple. Pictures and diagrams would help.

Again Drew, my hat is off to you. I could not have done what you did had it happened to me.

Drew, I admire your skills. If the same had happened to me I very much doubt it would have ended well. I do not have your skills. I read an article in a sailing magazine many, many months ago I think by Ralph Naranjo (spelling

On my "to do" list is to check the "chainplates" port and starboard on S/V Tadpole. Initially I had removed the two circular wood cover plates (4" diam) on each side hoping to be able to look up to the chainplates with a small mirror and light. This did not work.

I am now planning on removing the large plastic (fiberglass

My question is this: Exactly what should I be expecting to be looking at on a 1977 Ty Weekender (Hull #1400)

If there is corrosion in these plates (assuming I am correct that they are embedded in fiberglass), what are the physical signs of corrosion that I should expect to see

If corrosion is present, what is the procedure for repairing

OJ, I could really use your help on this

The good news, if it is good news, is that there does not appear to be anything readily observable that looks like rust, corrosion, etc. On deck, the plates that are fastened to the deck appear to be without any rust or corrosion. The turnbuckles themselves also appear to be without rust or corrosion. In the cabin I do not see any observable rust or corrosion trails, etc. but I have not yet opened up or removed the large plastic panels.

Any and all help is much appreciated. Please remember I am a dummy.

Again Drew, my hat is off to you. I could not have done what you did had it happened to me.

Fair winds,

Robert

Sea Hunt a/k/a "The Tadpole Sailor"

CDSOA #1097

Robert

Sea Hunt a/k/a "The Tadpole Sailor"

CDSOA #1097

Thanks guys for the info, but for some reason, I don't think CD used the same bolts on Sharkbait's typhoon as they did on mine, and carriage bolt was a poor choice of words on my part. From Sharkbait's picture, the bolt has that aqua green patina you get from bronze. The through bolt that failed on my typhoon (1982 model) was stainless steel at one time. I'll try to attach an image here.[img]

I've tried to get what is left of the bolt that failed (no head left on it) and the remaining chainplate bolt to budge with out success. I had no problem backing off the nuts on either bolt. It seems that these bolts corroded between the chainplate and the deck (no way to really see it till its too late). Now that they are rusted, they have expanded in their holes and will not budge.

Does anyone have a suggestion for how to get them out without destroying the deck around them?[/img]

I've tried to get what is left of the bolt that failed (no head left on it) and the remaining chainplate bolt to budge with out success. I had no problem backing off the nuts on either bolt. It seems that these bolts corroded between the chainplate and the deck (no way to really see it till its too late). Now that they are rusted, they have expanded in their holes and will not budge.

Does anyone have a suggestion for how to get them out without destroying the deck around them?[/img]

Greh3595

- Markst95

- Posts: 628

- Joined: Aug 5th, '08, 10:04

- Location: 1972 Typhoon Weekender "SWIFT" Hull #289 Narragansett Bay, RI

These are off my 1972 Weekender. I don't think there is any steel reinforcing plate in the deck, but the area underneath is solid fiberglass. I have the aforementioned side pockets, but mine have small covered ports that unscrew to gain access to the bolts. I'm pretty sure they were original.

<a href="http://i365.photobucket.com/albums/oo99 ... nplate.jpg" target="_blank"><img width="600" src="http://i365.photobucket.com/albums/oo99 ... e.jpg"></a>

<a href="http://i365.photobucket.com/albums/oo99 ... nplate.jpg" target="_blank"><img width="600" src="http://i365.photobucket.com/albums/oo99 ... e.jpg"></a>

Sea Hunt,

Just saw your post. I can't answer all of your questions as I am learning this one as I go.

If your boat is like mine, you will have two stainless steel 1/4 bolts that run from the chain plate on deck through the deck. I have the same fiberglass trim pieces inside the cabin that were apparently installed to create a false bulkhead - gives the area where the chainplates for the shrouds bolt through the deck a feeling that they are built very massive for the size of the boat. Unfortunately, the truth is all these fiberglas covers do is protrude into the cabin and make it really hard, no impossible, to visually inspect the chainplate bolts. It took me only a few minutes to remove dozen or so screws and pull the unit free. I think they bedded it in with something less than 3M 5200 so it wasn't too hard to get it off. Work the caulk loose around the edges with a couple of screwdrivers wedged in the edges. You pretty much have to remove this to really see the through bolts holding the chainplates to the deck, and having removed them, there is still an irritating small round hole giving access to those bolts.

Much to my surprise, there was no reinforcement in the form of a stainless steel plate visible where the bolts come through the deck. Unless they glassed something in, and I don't see any bulge below the deck so I don't think the did, there isn't any reinforcement. If you find this condition with your Typhoon, I'd suggest ordering some stainless steel plates to reinforce this area of hte deck.

Definitely pull and replade your chainplate bolts because there is no way to visually detect deterioration. Mine looked fine, till one failed.

Hope this helps.

Just saw your post. I can't answer all of your questions as I am learning this one as I go.

If your boat is like mine, you will have two stainless steel 1/4 bolts that run from the chain plate on deck through the deck. I have the same fiberglass trim pieces inside the cabin that were apparently installed to create a false bulkhead - gives the area where the chainplates for the shrouds bolt through the deck a feeling that they are built very massive for the size of the boat. Unfortunately, the truth is all these fiberglas covers do is protrude into the cabin and make it really hard, no impossible, to visually inspect the chainplate bolts. It took me only a few minutes to remove dozen or so screws and pull the unit free. I think they bedded it in with something less than 3M 5200 so it wasn't too hard to get it off. Work the caulk loose around the edges with a couple of screwdrivers wedged in the edges. You pretty much have to remove this to really see the through bolts holding the chainplates to the deck, and having removed them, there is still an irritating small round hole giving access to those bolts.

Much to my surprise, there was no reinforcement in the form of a stainless steel plate visible where the bolts come through the deck. Unless they glassed something in, and I don't see any bulge below the deck so I don't think the did, there isn't any reinforcement. If you find this condition with your Typhoon, I'd suggest ordering some stainless steel plates to reinforce this area of hte deck.

Definitely pull and replade your chainplate bolts because there is no way to visually detect deterioration. Mine looked fine, till one failed.

Hope this helps.

Greh3595

Markst,

I wish I had your nice bronze chainplates right about now. The system CD used on my boat (1982) is very different, but like your boat, there does not appear to be a backing plate on the cabin side of the deck. My boat has a stainless steel plate. I'd post a picture but I can't figure out how to up load to this forum.

I wish I had your nice bronze chainplates right about now. The system CD used on my boat (1982) is very different, but like your boat, there does not appear to be a backing plate on the cabin side of the deck. My boat has a stainless steel plate. I'd post a picture but I can't figure out how to up load to this forum.

Greh3595

-

Oswego John

- Posts: 3535

- Joined: Feb 5th, '05, 20:42

- Location: '66 Typhoon "Grace", Hull # 42, Schooner "Ontario", CD 85D Hull #1

Yo Sea Hunt

Hey Paisano, come stai?

I don't know what order to say a few things. I guess the first thing I'll bring up is repairing the chain plates, (if they do, indeed, need repairing). As was mentioned previously, the chain plates don't seem to cause any problems, it's the fasteners that hold them in place.

I see no need in dropping the mast when working on them. You have four shrouds to inspect and possibly replace the hardware. I only work on one at a time. Without placing any load on it, the mast will remain erect with one shroud removed. For the faint of heart, you can always make a loop in the removed shroud and secure the loop with one or two wire rope clips. Then fashion a temporary shroud from the loop to another spot along the toe rail.

I could be wrong, but I don't think rust is common in the chain plate area. The picture that Sharkbait sent in looks to me like the damage to the bolt is caused more from electrolysis that by rust. Again, not having a closer look, I could be wrong on this assumption. The bronze family will show a greenish, cupric oxide patina, but no rust. The iron family will show brownish rust, ferous oxide.

When you install a SS chain plate and use a dissimilar metal for the fasteners, you create an electrical battery which, in time, will corrode and eat away the less noble metal. Any exposure to moisture as an electrolyte will exacerbate the corrosion process. Moral of the story, don't mix the metals being used. Prevent moisture intrusion as much as possible. Use an anti-ox compound between metals being used.

Ciao,

Oswego Giovanni

I don't know what order to say a few things. I guess the first thing I'll bring up is repairing the chain plates, (if they do, indeed, need repairing). As was mentioned previously, the chain plates don't seem to cause any problems, it's the fasteners that hold them in place.

I see no need in dropping the mast when working on them. You have four shrouds to inspect and possibly replace the hardware. I only work on one at a time. Without placing any load on it, the mast will remain erect with one shroud removed. For the faint of heart, you can always make a loop in the removed shroud and secure the loop with one or two wire rope clips. Then fashion a temporary shroud from the loop to another spot along the toe rail.

I could be wrong, but I don't think rust is common in the chain plate area. The picture that Sharkbait sent in looks to me like the damage to the bolt is caused more from electrolysis that by rust. Again, not having a closer look, I could be wrong on this assumption. The bronze family will show a greenish, cupric oxide patina, but no rust. The iron family will show brownish rust, ferous oxide.

When you install a SS chain plate and use a dissimilar metal for the fasteners, you create an electrical battery which, in time, will corrode and eat away the less noble metal. Any exposure to moisture as an electrolyte will exacerbate the corrosion process. Moral of the story, don't mix the metals being used. Prevent moisture intrusion as much as possible. Use an anti-ox compound between metals being used.

Ciao,

Oswego Giovanni

"If I rest, I rust"

Voting Member #490

Voting Member #490

- Sea Hunt

- Posts: 1310

- Joined: Jan 29th, '06, 23:14

- Location: Former caretaker of 1977 Cape Dory Typhoon Weekender (Hull #1400) "S/V Tadpole"

Caio Giovanni:

Sta bene, grazie. Tuo Italiano sei eccellente

Sharbait:

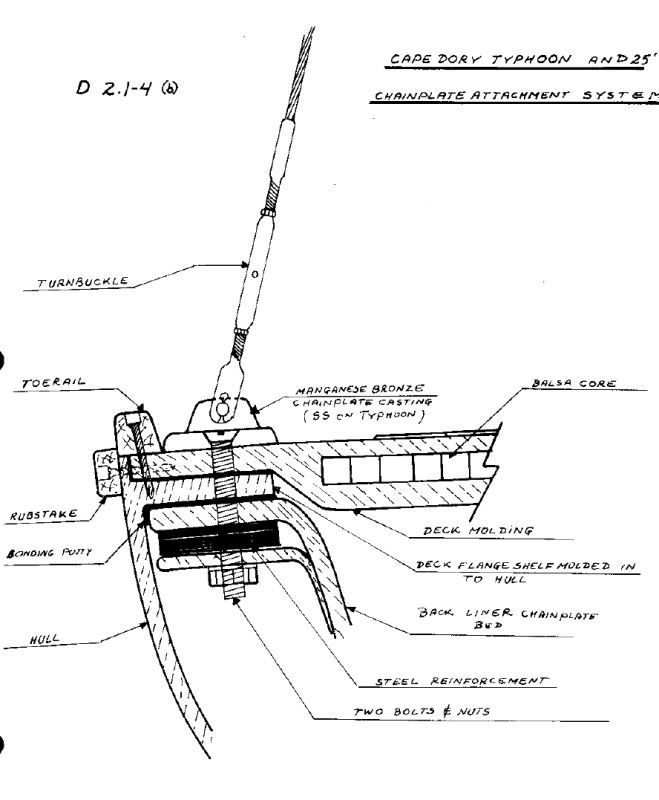

The picture/diagram appears to be exactly what I have on S/V Tadpole, including the "U" shaped stainless steel bracket on deck.

I guess what I am concerned about is what the diagram identifies as the "steel reinforcement". I assume this is a plate. If it corrodes and deteriorates, I assume it can allow the bold/nut to "pop out" causing the "U" bracket to come up off the deck. Also, if the bolts or nuts deteriorate, they can break, as apparently happened to Drew.

From the diagram, it appears almost impossible to inspect the "steel reinforcement" plate because it is covered over by the "backliner chainplate bed" from above and below the "steel reinforcement" plate with only the tip of the two bolts and nuts protruding. I guess maybe if the tips of the bolts and nuts appear rusted then you should "assume" the "steel reinforcement" plate is rusting also

Sharkbait, I very much appreciate you posting the diagram. I remembered seeing it in one the manuals but I could not find it earlier when I was searching. Thank you.

Caio

Sta bene, grazie. Tuo Italiano sei eccellente

Sharbait:

The picture/diagram appears to be exactly what I have on S/V Tadpole, including the "U" shaped stainless steel bracket on deck.

I guess what I am concerned about is what the diagram identifies as the "steel reinforcement". I assume this is a plate. If it corrodes and deteriorates, I assume it can allow the bold/nut to "pop out" causing the "U" bracket to come up off the deck. Also, if the bolts or nuts deteriorate, they can break, as apparently happened to Drew.

From the diagram, it appears almost impossible to inspect the "steel reinforcement" plate because it is covered over by the "backliner chainplate bed" from above and below the "steel reinforcement" plate with only the tip of the two bolts and nuts protruding. I guess maybe if the tips of the bolts and nuts appear rusted then you should "assume" the "steel reinforcement" plate is rusting also

Sharkbait, I very much appreciate you posting the diagram. I remembered seeing it in one the manuals but I could not find it earlier when I was searching. Thank you.

Caio

Fair winds,

Robert

Sea Hunt a/k/a "The Tadpole Sailor"

CDSOA #1097

Robert

Sea Hunt a/k/a "The Tadpole Sailor"

CDSOA #1097

After one of the bolts broke while I was trying to remove them it was apparent that there was major corrosion between the topside deck and the inner most visible plate. This is why I decided major surgery was necessary. When I drilled the holes out after punching the corroded screws I got a lot of rusty steel residue. I figured the steel plate and the stainless steel bolts shouldn't come in contact with each other. This is why I decided to enlarge the holes and filled them with reinforced epoxy.

Have A Nice Day