Question: Stuffing box--moldable packing

Moderator: Jim Walsh

- M. R. Bober

- Posts: 1122

- Joined: Feb 6th, '05, 08:59

- Location: CARETAKER CD28 Flybridge Trawler

Question: Stuffing box--moldable packing

Does anyone have first hand experience with this product: http://www.westmarine.com/webapp/wcs/st ... sNum=50424

I will be repacking the stuffing box and the moldable packing seems too good to not be in common usage. If you have used it, I would be interested in your opinion.

Mitchell Bober

Sunny Lancaster, (Where I usually use a fork for stuffing.) VA

I will be repacking the stuffing box and the moldable packing seems too good to not be in common usage. If you have used it, I would be interested in your opinion.

Mitchell Bober

Sunny Lancaster, (Where I usually use a fork for stuffing.) VA

CDSOA Founding Member

MOLDABLE PACKING

Mitchell,

Some information suggests that it increases the possibility of crevice corrosion to the shaft. The Graphite packing was pushed for a while too but galvanic corrosion is an issue with it. Personally, I would stick with ordinary flax, I like the Teflon version, or go to a drip-less shaft seal.

Some information suggests that it increases the possibility of crevice corrosion to the shaft. The Graphite packing was pushed for a while too but galvanic corrosion is an issue with it. Personally, I would stick with ordinary flax, I like the Teflon version, or go to a drip-less shaft seal.

Lee

S/V Solomon Lee

S/V Solomon Lee

- Zeida

- Posts: 600

- Joined: May 27th, '05, 07:10

- Location: 1982 CD33 "Bandolera II" Hull #73Key Biscayne-Miami, Florida

- Contact:

Very interested in your comment that the graphite packing may lead to some corrosion on the shaft. I am currently using it, the Goretex graphite packing, on Bandolera. Will be anxious to replace it asap if indeed there is the possibility of shaft damage. Where is this report coming from? Since I normally haul out every 3 yrs. and am not due yet for another year, I would not like to wait to make the change if the graphite packing is not 100% good. Your comments greatly appreciated.

Zeida

Zeida

Zeida

CDSOA Member

CDSOA Member

-

Maine Sail

- Posts: 839

- Joined: Feb 8th, '06, 18:30

- Location: Canadian Sailcraft 36T

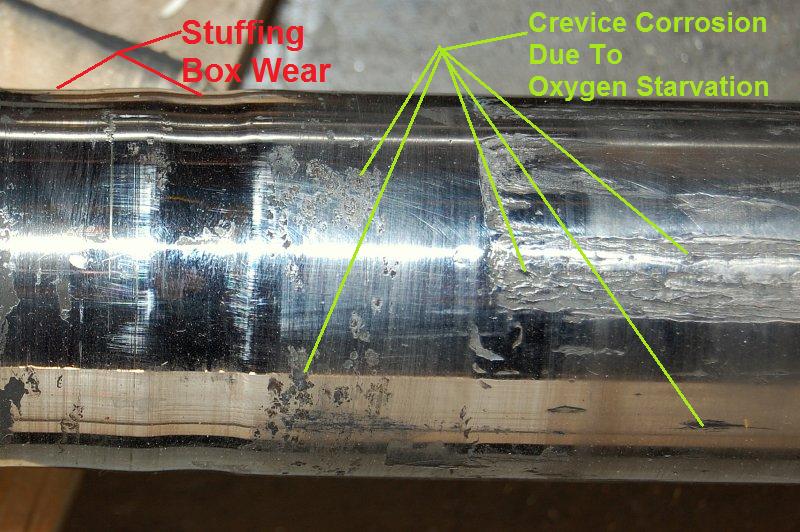

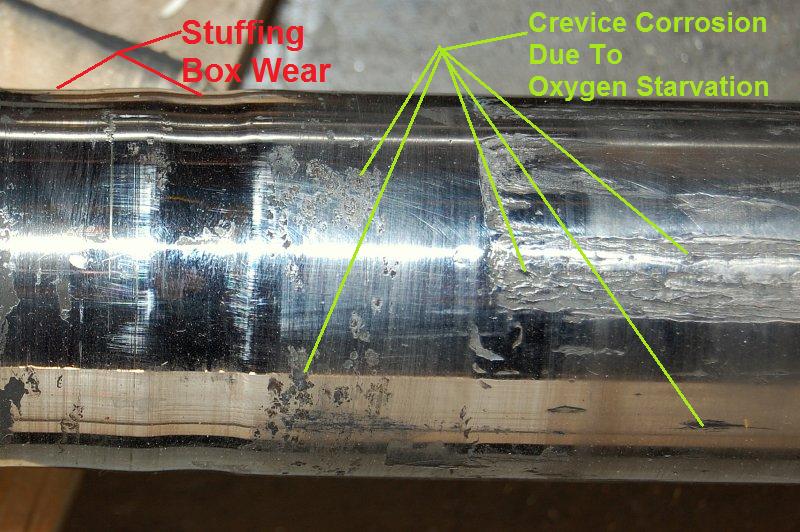

This shaft had GFO in it for one season. Had been fine the year before. I don't use GFO or the other graphite impregnated variants on bronze shafts for this reason.

It was completely dezincified in one year. With an AQ22 shaft you see corrosion issues a lot less than with bronze. You really need to keep up with your zincs if using a bronze shaft and a graphite based packing. The zincs on this one were still good but the zinc in the shaft under the packing, not so much.

There were even spots of dezincification in the middle of the shaft.

By completely starving the shaft log of oxygen by making it totally drip-free you can accelerate corrosion of even an Aqualoy 22 shaft.

A little dripping allows more than just lubrication it also allows air to be purged out of the shaft log that becomes entrapped up in there. It also allows fresh oxygenated water to flow into the shaft log which helps prevent corrosion due to an oxygen starved condition..

It was completely dezincified in one year. With an AQ22 shaft you see corrosion issues a lot less than with bronze. You really need to keep up with your zincs if using a bronze shaft and a graphite based packing. The zincs on this one were still good but the zinc in the shaft under the packing, not so much.

There were even spots of dezincification in the middle of the shaft.

By completely starving the shaft log of oxygen by making it totally drip-free you can accelerate corrosion of even an Aqualoy 22 shaft.

A little dripping allows more than just lubrication it also allows air to be purged out of the shaft log that becomes entrapped up in there. It also allows fresh oxygenated water to flow into the shaft log which helps prevent corrosion due to an oxygen starved condition..

Packing

Active (Anodic)

Magnesium

Mg alloy AZ-31B

Mg alloy HK-31A

Zinc (hot-dip, die cast, or plated)

Beryllium (hot pressed)

Al 7072 clad on 7075

Al 2014-T3

Al 1160-H14

Al 7079-T6

Cadmium (plated)

Uranium

Al 218 (die cast)

Al 5052-0

Al 5052-H12

Al 5456-0, H353

Al 5052-H32

Al 1100-0

Al 3003-H25

Al 6061-T6

Al A360 (die cast)

Al 7075-T6

Al 6061-0

Indium

Al 2014-0

Al 2024-T4

Al 5052-H16

Tin (plated)

Stainless steel 430 (active)

Lead

Steel 1010

Iron (cast)

Stainless steel 410 (active)

Copper (plated, cast, or wrought)

Nickel (plated)

Chromium (Plated)

Tantalum

AM350 (active)

Stainless steel 310 (active)

Stainless steel 301 (active)

Stainless steel 304 (active)

Stainless steel 430 (active)

Stainless steel 410 (active)

Stainless steel 17-7PH (active)

Tungsten

Niobium (columbium) 1% Zr

Brass, Yellow, 268

Uranium 8% Mo

Brass, Naval, 464

Yellow Brass

Muntz Metal 280

Brass (plated)

Nickel-silver (18% Ni)

Stainless steel 316L (active)

Bronze 220

Copper 110

Red Brass

Stainless steel 347 (active)

Molybdenum, Commercial pure

Copper-nickel 715

Admiralty brass

Stainless steel 202 (active)

Bronze, Phosphor 534 (B-1)

Monel 400

Stainless steel 201 (active)

Carpenter 20 (active)

Stainless steel 321 (active)

Stainless steel 316 (active)

Stainless steel 309 (active)

Stainless steel 17-7PH (passive)

Silicone Bronze 655

Stainless steel 304 (passive)

Stainless steel 301 (passive)

Stainless steel 321 (passive)

Stainless steel 201 (passive)

Stainless steel 286 (passive)

Stainless steel 316L (passive)

AM355 (active)

Stainless steel 202 (passive)

Carpenter 20 (passive)

AM355 (passive)

A286 (passive)

Titanium 5A1, 2.5 Sn

Titanium 13V, 11Cr, 3Al (annealed)

Titanium 6Al, 4V (solution treated and aged)

Titanium 6Al, 4V (anneal)

Titanium 8Mn

Titanium 13V, 11Cr 3Al (solution heat treated and aged)

Titanium 75A

AM350 (passive)

Silver

Gold

Graphite

End - Noble (Less Active, Cathodic)

Magnesium

Mg alloy AZ-31B

Mg alloy HK-31A

Zinc (hot-dip, die cast, or plated)

Beryllium (hot pressed)

Al 7072 clad on 7075

Al 2014-T3

Al 1160-H14

Al 7079-T6

Cadmium (plated)

Uranium

Al 218 (die cast)

Al 5052-0

Al 5052-H12

Al 5456-0, H353

Al 5052-H32

Al 1100-0

Al 3003-H25

Al 6061-T6

Al A360 (die cast)

Al 7075-T6

Al 6061-0

Indium

Al 2014-0

Al 2024-T4

Al 5052-H16

Tin (plated)

Stainless steel 430 (active)

Lead

Steel 1010

Iron (cast)

Stainless steel 410 (active)

Copper (plated, cast, or wrought)

Nickel (plated)

Chromium (Plated)

Tantalum

AM350 (active)

Stainless steel 310 (active)

Stainless steel 301 (active)

Stainless steel 304 (active)

Stainless steel 430 (active)

Stainless steel 410 (active)

Stainless steel 17-7PH (active)

Tungsten

Niobium (columbium) 1% Zr

Brass, Yellow, 268

Uranium 8% Mo

Brass, Naval, 464

Yellow Brass

Muntz Metal 280

Brass (plated)

Nickel-silver (18% Ni)

Stainless steel 316L (active)

Bronze 220

Copper 110

Red Brass

Stainless steel 347 (active)

Molybdenum, Commercial pure

Copper-nickel 715

Admiralty brass

Stainless steel 202 (active)

Bronze, Phosphor 534 (B-1)

Monel 400

Stainless steel 201 (active)

Carpenter 20 (active)

Stainless steel 321 (active)

Stainless steel 316 (active)

Stainless steel 309 (active)

Stainless steel 17-7PH (passive)

Silicone Bronze 655

Stainless steel 304 (passive)

Stainless steel 301 (passive)

Stainless steel 321 (passive)

Stainless steel 201 (passive)

Stainless steel 286 (passive)

Stainless steel 316L (passive)

AM355 (active)

Stainless steel 202 (passive)

Carpenter 20 (passive)

AM355 (passive)

A286 (passive)

Titanium 5A1, 2.5 Sn

Titanium 13V, 11Cr, 3Al (annealed)

Titanium 6Al, 4V (solution treated and aged)

Titanium 6Al, 4V (anneal)

Titanium 8Mn

Titanium 13V, 11Cr 3Al (solution heat treated and aged)

Titanium 75A

AM350 (passive)

Silver

Gold

Graphite

End - Noble (Less Active, Cathodic)

Lee

S/V Solomon Lee

S/V Solomon Lee

- Bob Ohler

- Posts: 610

- Joined: Feb 5th, '05, 14:11

- Location: CD30 1984 Hull# 335 Aloha Spirit, Chesapeake Bay

Maine Sail... GFO = ?

"GFO" is graphite packing?

Bob Ohler

CDSOA Member #188

CD30B, Hull # 335

sv Aloha Spirit

CDSOA Member #188

CD30B, Hull # 335

sv Aloha Spirit

-

Maine Sail

- Posts: 839

- Joined: Feb 8th, '06, 18:30

- Location: Canadian Sailcraft 36T

Re: Maine Sail... GFO = ?

It is graphite impregnated PTFE packing. The graphite helps it transfer heat better and adds lubricity. This can come at a cost though and that cost is the potential for increased corrosion as graphite is at the top of the galvanic scale..Bob Ohler wrote:"GFO" is graphite packing?

-

S/V Necessity

- Posts: 147

- Joined: Jun 13th, '06, 23:38

- Location: 1981 CD28 #305

Columbia, MO

- M. R. Bober

- Posts: 1122

- Joined: Feb 6th, '05, 08:59

- Location: CARETAKER CD28 Flybridge Trawler

- fenixrises

- Posts: 450

- Joined: Feb 13th, '05, 08:01

- Location: SunShine S2 11c

- Contact:

A new idea

Hi all,

My friend Tim, who builds the 48' cats, came up with a simple very cost effective solution to this question.

Much like the "Dripless" stuffing boxes his system does not drip and is simplicity itself. A word of caution, this will only work on a clean, ungrooved, noncorroded shaft.

Instead od the traditional packing gland with nut, locknut and packing replace either the entire thing if it is a seperate piece or just the nut, locknut and packing(if you have the fore and aft length needed) with a piece of flexible hose of the same type used to join the packing gland to the shaft log going through the hull.

Inside this piece of tubing insert a shortened piece of shaft bearing, it should be long enough to allow for two hose clamps.

Next install on the shaft at least two but 3~6 would be better standard round oil seals. Two of these fit inside the new tubing, right next to each other. Install a hose clamp or two to hold the seals in place. Bingo! Dripless packing.

The seals need to be installed facing the right direction, with the "Lip" aft !!

The extra seals rotate with the shaft until used. You just slide the old seals toward the engine and cut them off with a pair of dykes. Then slide the next two in place and reclamp. Since new seals require removing the shaft from the engine coupler, extras already installed means total replacement of seals need be done only once every few years.

Tim has used this system on every boat he builds and remember with catamarans that means two shafts on every boat. Many thousands of hours have been logged with this system without failure, for a fraction of the price of "dripless" packing glands.

One other note. Standard oil seals use spring steel coil springs to help hold the neoprene against the shaft. They need to be removed before installing the seals as spring steel will be reduced to a wad of rust in the marine enviroment in nothing flat. The water pressure against the rubber seals is very little and the springs are not needed.

To help reduce SS corrosion a simple water injection system can be install on the boat. Just put a "TEE" fitting in the raw water line between the engine and the exhaust elbow. The leg of the tee should be reduced to a 1/4" hose barb. Then drill and tap the shaft log on the top somewhere you can get at it. Insert another 1/4" hose barb, connect the two with 1/4" hose. Viola!! You now have fresh salt water being injected into the shaft log and out through the shaft bearing.

Take care,

Fred

My friend Tim, who builds the 48' cats, came up with a simple very cost effective solution to this question.

Much like the "Dripless" stuffing boxes his system does not drip and is simplicity itself. A word of caution, this will only work on a clean, ungrooved, noncorroded shaft.

Instead od the traditional packing gland with nut, locknut and packing replace either the entire thing if it is a seperate piece or just the nut, locknut and packing(if you have the fore and aft length needed) with a piece of flexible hose of the same type used to join the packing gland to the shaft log going through the hull.

Inside this piece of tubing insert a shortened piece of shaft bearing, it should be long enough to allow for two hose clamps.

Next install on the shaft at least two but 3~6 would be better standard round oil seals. Two of these fit inside the new tubing, right next to each other. Install a hose clamp or two to hold the seals in place. Bingo! Dripless packing.

The seals need to be installed facing the right direction, with the "Lip" aft !!

The extra seals rotate with the shaft until used. You just slide the old seals toward the engine and cut them off with a pair of dykes. Then slide the next two in place and reclamp. Since new seals require removing the shaft from the engine coupler, extras already installed means total replacement of seals need be done only once every few years.

Tim has used this system on every boat he builds and remember with catamarans that means two shafts on every boat. Many thousands of hours have been logged with this system without failure, for a fraction of the price of "dripless" packing glands.

One other note. Standard oil seals use spring steel coil springs to help hold the neoprene against the shaft. They need to be removed before installing the seals as spring steel will be reduced to a wad of rust in the marine enviroment in nothing flat. The water pressure against the rubber seals is very little and the springs are not needed.

To help reduce SS corrosion a simple water injection system can be install on the boat. Just put a "TEE" fitting in the raw water line between the engine and the exhaust elbow. The leg of the tee should be reduced to a 1/4" hose barb. Then drill and tap the shaft log on the top somewhere you can get at it. Insert another 1/4" hose barb, connect the two with 1/4" hose. Viola!! You now have fresh salt water being injected into the shaft log and out through the shaft bearing.

Take care,

Fred

You should always have an odd number of holes in your boat!

- Kevin Kaldenbach

- Posts: 346

- Joined: Aug 24th, '08, 16:26

- Location: Cape Dory 31 “Kerry Ann“. Currently in Corpus Christi TX and Typhoon Weekender “Wimpyâ€

reply

Fred, keep in mind that oil seals are actually lubricated by the oil. With a double seal the external seal is most likely run dry so that could be a problem. A friend told me he had a boat that had a zert on the stuffing box and he just pumped grease in it and it did not leak. What do you know about this set up?

Kevin

CD 31 "Kerry Ann"

kaldenbach.us

CD 31 "Kerry Ann"

kaldenbach.us

- fenixrises

- Posts: 450

- Joined: Feb 13th, '05, 08:01

- Location: SunShine S2 11c

- Contact:

Reply to Kevin

Hi all,

Yes you can install a "Zerk" fitting in the shaft log somewhere and pump the thing full of waterproof grease. Zerk fittings are available in SS. But remember this will no rplace the packing. Water pressure may well, over time, force the grease through the packing nut and it will be filled with salt water very quick. With no packing the water will of course run into the bilge.

Take care,

Fred

P.S. The forward oil seal does not wear if all is prelubed with grease before assembly, something you would do anyway to ease assembly.

Yes you can install a "Zerk" fitting in the shaft log somewhere and pump the thing full of waterproof grease. Zerk fittings are available in SS. But remember this will no rplace the packing. Water pressure may well, over time, force the grease through the packing nut and it will be filled with salt water very quick. With no packing the water will of course run into the bilge.

Take care,

Fred

P.S. The forward oil seal does not wear if all is prelubed with grease before assembly, something you would do anyway to ease assembly.

You should always have an odd number of holes in your boat!

Packing

Zeida, et al,

I have been using the Teflon packing on mine and other boats for years without problem. I also know several mechanics that install the Teflon packing and also use Teflon grease like Superlube with it. This allows them to tighten the packing just enough to stop dripping. I have been watching them do this for about 7 years now and have yet to see a shaft scored or a crevice corrosion issue. Go figure. Anyway, this is the packing I use.

http://www.jamestowndistributors.com/us ... ax+Packing#

I have been using the Teflon packing on mine and other boats for years without problem. I also know several mechanics that install the Teflon packing and also use Teflon grease like Superlube with it. This allows them to tighten the packing just enough to stop dripping. I have been watching them do this for about 7 years now and have yet to see a shaft scored or a crevice corrosion issue. Go figure. Anyway, this is the packing I use.

http://www.jamestowndistributors.com/us ... ax+Packing#

Lee

S/V Solomon Lee

S/V Solomon Lee

Re: Question: Stuffing box--moldable packing

Any updates on this old thread? Someday I may install a dripless shaft but for now I have to try to salvage the troubled relationship with my current drive train. I have been using regular PTFE packing and have been leaking and worrying . . .. I have some GTU here now as well as more PTFE and syntef but I am really thinking about Mitchell's original post: has anyone tried the seemingly "too good to be true" moldable dripless packing that West sells? I know Maine Sail is of the opinion that it will lead to corrosion but I am thinking I already have so many bad things happening back there I'd be thrilled to get a couple of years in . . .. Some encouragement please!

Desperately yours,

Dreaming of Dripless

Desperately yours,

Dreaming of Dripless