Hi all...

First, I'm most thankful to Sea Hunt who took the time to graciously post the inquiry on my behalf. He went sailing with me on Bandolera II, a CD-33 a couple of weeks ago and as we were almost back at my slip, the engine just stopped and would not start again. We were towed in.

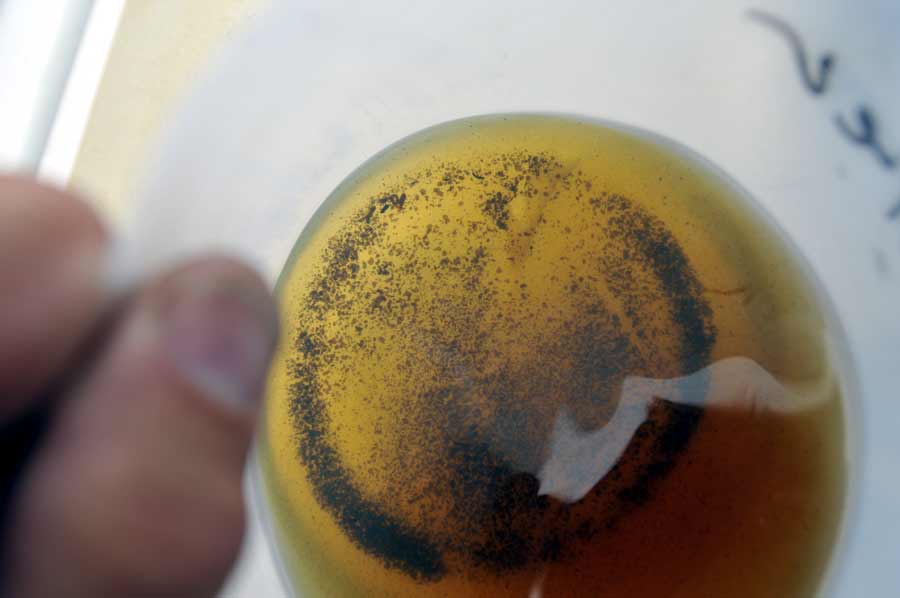

Upon inspection, when opening the top of the Racor filter, we saw there was not enough fuel in there... obviously, something went wrong along the fuel lines. Clogged, or crud from the tank, etc. A couple of days later, I cleaned up Racor as well as I could, replaced the filter which was absolutely full of junk, filled it up with new fuel. I also replaced the secondary fuel filter, cleaned the electric fuel pump. Then bled the system. My engine started again fine. However, since I have owned the boat-12 yrs. now, I have never cleaned that fuel tank... neither the PO. So I can only imagine what can be in there. I did not want to start my engine again without trying to do something about the fuel in that tank and trying to somehow clean it, if possible.

Yes, I got quotes from $350 to $400. for "fuel polishing". BUT... the fuel tank on my 33 is in an impossible access place. I guess that to take it out, it would have to be cut up in place in order to remove it in pieces through the access in the port cockpit locker. The fuel access is via the stbd. locker, through a small cap opening, in a small glassed-in shelf, and only a measuring stick fits in there. To fuel up, I insert a small funnel and filter the new fuel I put in. It carries 20 gals. of fuel. It does not have any type of fuel gage or anything. Just, on top of the tank, one small "out" for the main fuel line that goes directly to the electric fuel pump (from there to the Racor..etc.) - another small "vent" hose that leads all the way to the stern - and a small "return" line from the injectors. These small outlets are almost impossible to reach, unless you are willing to really scratch your hands big time (which I do anyway).

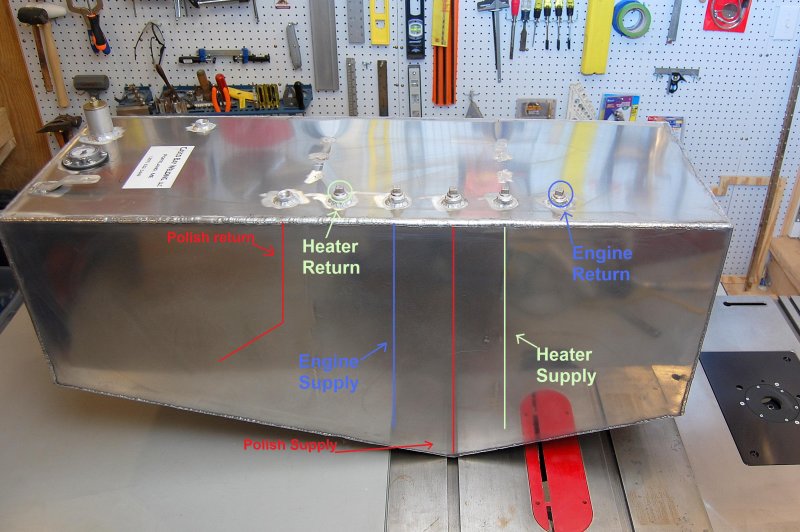

After looking at Maine Sail's set-up I am green with envy. My boat lives in the water all year round. I do not have a work area such as his, much less the ability to do such things. If I were to replace my tank with a new one, it would become a task for myself and a plumber doing it together in order to make the project affordable. Actually, the more I think about it, the more possible the project looks.

Any recommendations would be extremely welcome. I will take photos today of my situation and post them for advise. Thanks.