Seacocks

Moderator: Jim Walsh

- Alan Holman

- Posts: 62

- Joined: Sep 27th, '09, 13:42

- Location: As of 10/11/09 the proud new owner of Solo Noi(renaming scheduled for summer 2010)

Seacocks

I need to replace the gate vales on my '76 CD25 and I'm looking at three different brands and types. I need some advice to help me sort this out.

The cheapest are made of Marelon, a material I have never heard of. They are made by Forespar.

Appollo bronze are the next best price, but about twice what the Marelon cost. They are described as full-port.

Groco makes a bronze seacock described as full-flow, they're the most expensive.

What is Marelon? What is the difference between full-port and full-flow? I"m sailing in salt water five months of the year, anyone have any suggestions, recommendations?

Thanks,

The Meddler

The cheapest are made of Marelon, a material I have never heard of. They are made by Forespar.

Appollo bronze are the next best price, but about twice what the Marelon cost. They are described as full-port.

Groco makes a bronze seacock described as full-flow, they're the most expensive.

What is Marelon? What is the difference between full-port and full-flow? I"m sailing in salt water five months of the year, anyone have any suggestions, recommendations?

Thanks,

The Meddler

Sometimes your vessel's becalmed for days and weeks on end,

Sometimes the winds of life will blow you off your course, my friend,

But the wind is sure to veer, you must stay aboard and steer,

And long may your big jib draw!

Sometimes the winds of life will blow you off your course, my friend,

But the wind is sure to veer, you must stay aboard and steer,

And long may your big jib draw!

Meddler,

Marelon is a proprietary name for a reinforced polymer. It is different than Nyglass and is really tough stuff. If you want to see for yourself buy one of the Marelon hose barbs and put it in a vise and try to destroy it with a hammer and visegrips. It does have some advantages such as eliminating the possible of stray current corrosion and less of a possibility that a thru hull could be blown out the bottom in a lightning strike (God forbid). That said though, Marelon valves can get stiff without use and lubrication. The handles are usually the weak point, and the handles have been known to break when forcing a stiff valve. The hypothesis is that the material is somewhat permeable and the ball expands slightly over time causing the stiffness. Regardless, they are good stuff. As far as the others, both are good valves. I have used the Groco and Conbraco Apollo valves for years without problem. Personally, I would save the cash and buy the Conbraco seacocks over the Groco myself. In either case though, please use real seacocks with a mounting flange. Typical ball valves use tapered threads top and bottom. Thru hulls themselves are straight thread which results in a mix. Over time and degradation this can produce a problem. I will not bore you with all the details. The West Marine catalog has a very good explanation of the difference between a regular ball valve and a seacock if you are interested. Good luck any of the three you have cited will do the job just fine. You could also go with the tried and true Spartans too, but they will set you back more cash.

Marelon is a proprietary name for a reinforced polymer. It is different than Nyglass and is really tough stuff. If you want to see for yourself buy one of the Marelon hose barbs and put it in a vise and try to destroy it with a hammer and visegrips. It does have some advantages such as eliminating the possible of stray current corrosion and less of a possibility that a thru hull could be blown out the bottom in a lightning strike (God forbid). That said though, Marelon valves can get stiff without use and lubrication. The handles are usually the weak point, and the handles have been known to break when forcing a stiff valve. The hypothesis is that the material is somewhat permeable and the ball expands slightly over time causing the stiffness. Regardless, they are good stuff. As far as the others, both are good valves. I have used the Groco and Conbraco Apollo valves for years without problem. Personally, I would save the cash and buy the Conbraco seacocks over the Groco myself. In either case though, please use real seacocks with a mounting flange. Typical ball valves use tapered threads top and bottom. Thru hulls themselves are straight thread which results in a mix. Over time and degradation this can produce a problem. I will not bore you with all the details. The West Marine catalog has a very good explanation of the difference between a regular ball valve and a seacock if you are interested. Good luck any of the three you have cited will do the job just fine. You could also go with the tried and true Spartans too, but they will set you back more cash.

Lee

S/V Solomon Lee

S/V Solomon Lee

- tartansailor

- Posts: 1527

- Joined: Aug 30th, '05, 13:55

- Location: CD25, Renaissance, Milton, DE

Marelon

Marelon is DuPont's Zytel, a fancy name for nylon, and nylon does in fact absorb moisture, big time. I believe the (Reinforcement, ha!) filler is glass, but it could as well be mica. Best to keep the insides bathed in silicone grease.

Dick

Dick

- Sea Hunt

- Posts: 1310

- Joined: Jan 29th, '06, 23:14

- Location: Former caretaker of 1977 Cape Dory Typhoon Weekender (Hull #1400) "S/V Tadpole"

Meddler:

Lee's comment about Marelon handles breaking off was documented/reported in an article I read about a year ago. Unfortunately, being old and dumb, I do not remember where I read this article. It may have been an internet website. The article said they are prone to breaking and should not be used for thru hull fittings.

I was at the time researching installing new seacocks on my 1977 Typhoon Weekender (S/V Tadpole). At the end of the day I decided that when I next haul her out for bottom paint, etc. I will install Spartan seacocks. They are a little bit more expensive than other brands but they also never fail - so I am told .

.

Lee's comment about Marelon handles breaking off was documented/reported in an article I read about a year ago. Unfortunately, being old and dumb, I do not remember where I read this article. It may have been an internet website. The article said they are prone to breaking and should not be used for thru hull fittings.

I was at the time researching installing new seacocks on my 1977 Typhoon Weekender (S/V Tadpole). At the end of the day I decided that when I next haul her out for bottom paint, etc. I will install Spartan seacocks. They are a little bit more expensive than other brands but they also never fail - so I am told

Fair winds,

Robert

Sea Hunt a/k/a "The Tadpole Sailor"

CDSOA #1097

Robert

Sea Hunt a/k/a "The Tadpole Sailor"

CDSOA #1097

Meddler,

The only complaint I have about Spartans is that they will not hold up to neglect as well as the others, ie: Conbraco and Groco. The Teflon seats that the SS ball rides on still need to be lubricated on the others, but seizure due to corrosion is rarely a problem or let me say, not as often as with a tapered drum style like the Spartans. The Spartans are great valves, but they must be maintained, or as you can see from other posts, they will seize up. From my personal observations, this doesn't happen as often with seacocks that use the ball type arrangement. It is nice that the Spartans are made with a integral hose barb which has to be figured into the price of the others. For what its worth though, if it was not for the expense, and the time and effort required to glass up the bolt holes for the fasteners, I would replace all of my Spartans with Conbraco Apollo seacocks and use silicon bronze bolts, nuts and washers to secure the flanges. Its a lot less effort to smear some teflon grease on the ball every five years when I haul out than disassembling, lapping, cleaning, greasing, and adjusting the Spartans. Plus little dribbles are practically unheard of with the other style. Well just my two cents worth. Good luck and fair winds.

The only complaint I have about Spartans is that they will not hold up to neglect as well as the others, ie: Conbraco and Groco. The Teflon seats that the SS ball rides on still need to be lubricated on the others, but seizure due to corrosion is rarely a problem or let me say, not as often as with a tapered drum style like the Spartans. The Spartans are great valves, but they must be maintained, or as you can see from other posts, they will seize up. From my personal observations, this doesn't happen as often with seacocks that use the ball type arrangement. It is nice that the Spartans are made with a integral hose barb which has to be figured into the price of the others. For what its worth though, if it was not for the expense, and the time and effort required to glass up the bolt holes for the fasteners, I would replace all of my Spartans with Conbraco Apollo seacocks and use silicon bronze bolts, nuts and washers to secure the flanges. Its a lot less effort to smear some teflon grease on the ball every five years when I haul out than disassembling, lapping, cleaning, greasing, and adjusting the Spartans. Plus little dribbles are practically unheard of with the other style. Well just my two cents worth. Good luck and fair winds.

Lee

S/V Solomon Lee

S/V Solomon Lee

- Clay Stalker

- Posts: 390

- Joined: Feb 5th, '05, 12:07

- Location: 17' Town Class Sloop

Spartan vs. Marelon

Having owned boats with both, I can offer the following: Spartans are the most rugged and beautiful but require maintenance. Marelons are rugged, not so beautiful but functional, also require maintenance, and the handles can snap (but won't if you keep them lubricated). In summary, if $$ is not a factor, go with the Spartans. If $$ is a factor, the Marelons will outlive you. The difference in cost is significant. My obvious preference is Spartan, but I have never had a problem with Marelon.

Clay Stalker

Westmoreland, NH and Spofford Lake, NH

Westmoreland, NH and Spofford Lake, NH

-

Maine Sail

- Posts: 839

- Joined: Feb 8th, '06, 18:30

- Location: Canadian Sailcraft 36T

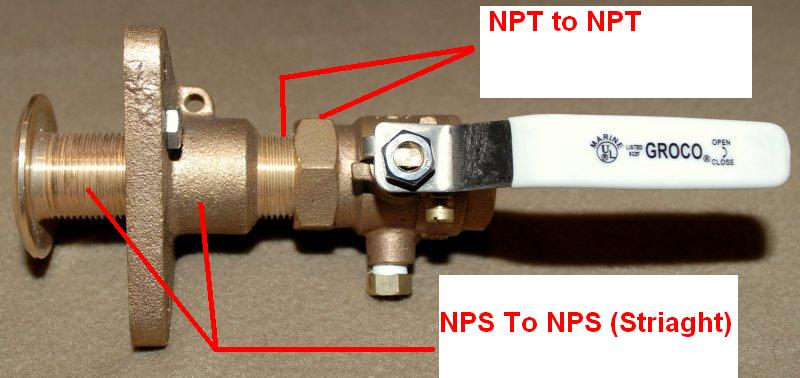

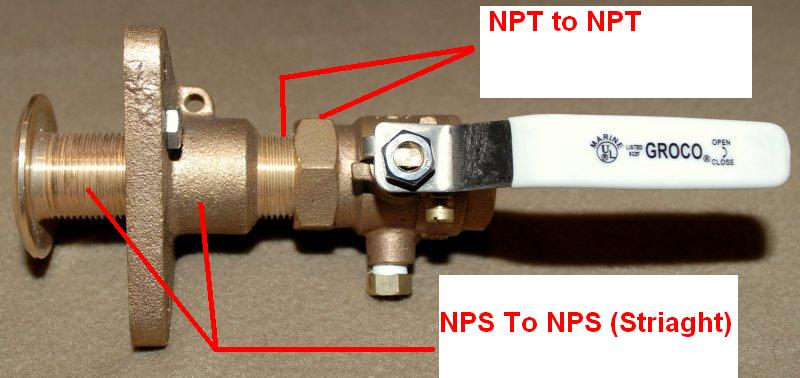

If you are considering using a proper flanged seacock you may want to consider the Groco Flanged adapter. These are perhaps one of the best seacock inventions to come along in a long while. The whole idea of the Groco flanged adapter is that the threads on the top of the flange, or inside of the hull, are NPT (tapered cut) just like a standard ball valve is.

The threads on the bottom of the flange, or facing the outside of the hull, are NPS (straight cut) to match the straight threads of a thru-hull.

The flanged adapter was invented for a number of reasons all of which make it one of the best inventions as of late for seacock technology.

Flanged Adapter Benefits:

#1 Matched threads between BV and adapter and thru-hull and adapter.

#2 Stronger than slapping a BV on a thru-hull and as strong as a flanged seacock as measured by cross sectional thickness.

#3 Saves money down the road because the valve replacement, which is always the first to fail, takes less than five or ten minutes and can be done in the water any where.

#4 Allows for easier plumbing configuration when low internal height to cabin sole etc. limit the total valve height.

#5 Can be permanently mounted to the hull and allows easy valve replacement in any location in the world without requiring a haul-out. NPT ball valves are easy to find or order most anywhere in the world, even in remote locations.

#6 Makes future valve replacements far less expensive and considerably less invasive and time consuming.

#7 Ball valves are less expensive than flanged seacocks so the second time you change a BV you are way ahead financially.

#8 Carrying one or two sizes of spare BV's, as a world cruiser, is much cheaper than carrying spare seacocks.

#9 Spare BV's can be used in a pinch for far more on your vessel than can a spare flanged seacock. A 3/4" BV is a good spare to have but a spare 3/4" flanged seacock is only a spare seacock.

#10 In a remote location, when you can't find a replacement seacock, nor a place to haul out or beach the vessel and wait for a tide, you can use any, brass, stainless, bronze or even copper NPT/NPT ball valve to get you back in business. Of course if you use sub par metals be sure to change it back out when you get to a local where bronze valves are available. If a flanged seacock fails to open or close you will need to replace the entire unit, or re-build and re-lap if Spartan, not just spin a valve off and replace it.

The #1 failure of BV's, as I have experienced, is the ball and seats not corrosion of the bronze body or thru-hull. When folks do not open or close the valves enough growth attaches to the closed ball and when opened it digs up the phenolic valve seat or scores the ball. The same type of scoring can happen on tapered cone valves, seen it, and repaired it, if they are not used enough.

It is almost always the BV that fails and not the thru-hull unless it was broken off because it was not installed into a flanged seacock or flanged adapter.

I cracked a thru-hull on my own boat in a storm. This was a valve on a thru-hull with no flange. My boat was quickly hauled and every seacock converted to flanges and through bolts. I got religion about flanges real fast..

I understand many are not aware of the flanged adapter. Inline BV's do not have to thread only onto a thru-hull, in fact doing so is usually a thread mis-match. Inline valves can be threaded onto a flanged adapter too.

Below is a flanged adapter:

P.S. Sorry for the MS Paint spelling error. I do actually know how to spell straight...

Hope the photo helps show how a flanged adapter works.

__________________

The threads on the bottom of the flange, or facing the outside of the hull, are NPS (straight cut) to match the straight threads of a thru-hull.

The flanged adapter was invented for a number of reasons all of which make it one of the best inventions as of late for seacock technology.

Flanged Adapter Benefits:

#1 Matched threads between BV and adapter and thru-hull and adapter.

#2 Stronger than slapping a BV on a thru-hull and as strong as a flanged seacock as measured by cross sectional thickness.

#3 Saves money down the road because the valve replacement, which is always the first to fail, takes less than five or ten minutes and can be done in the water any where.

#4 Allows for easier plumbing configuration when low internal height to cabin sole etc. limit the total valve height.

#5 Can be permanently mounted to the hull and allows easy valve replacement in any location in the world without requiring a haul-out. NPT ball valves are easy to find or order most anywhere in the world, even in remote locations.

#6 Makes future valve replacements far less expensive and considerably less invasive and time consuming.

#7 Ball valves are less expensive than flanged seacocks so the second time you change a BV you are way ahead financially.

#8 Carrying one or two sizes of spare BV's, as a world cruiser, is much cheaper than carrying spare seacocks.

#9 Spare BV's can be used in a pinch for far more on your vessel than can a spare flanged seacock. A 3/4" BV is a good spare to have but a spare 3/4" flanged seacock is only a spare seacock.

#10 In a remote location, when you can't find a replacement seacock, nor a place to haul out or beach the vessel and wait for a tide, you can use any, brass, stainless, bronze or even copper NPT/NPT ball valve to get you back in business. Of course if you use sub par metals be sure to change it back out when you get to a local where bronze valves are available. If a flanged seacock fails to open or close you will need to replace the entire unit, or re-build and re-lap if Spartan, not just spin a valve off and replace it.

The #1 failure of BV's, as I have experienced, is the ball and seats not corrosion of the bronze body or thru-hull. When folks do not open or close the valves enough growth attaches to the closed ball and when opened it digs up the phenolic valve seat or scores the ball. The same type of scoring can happen on tapered cone valves, seen it, and repaired it, if they are not used enough.

It is almost always the BV that fails and not the thru-hull unless it was broken off because it was not installed into a flanged seacock or flanged adapter.

I cracked a thru-hull on my own boat in a storm. This was a valve on a thru-hull with no flange. My boat was quickly hauled and every seacock converted to flanges and through bolts. I got religion about flanges real fast..

I understand many are not aware of the flanged adapter. Inline BV's do not have to thread only onto a thru-hull, in fact doing so is usually a thread mis-match. Inline valves can be threaded onto a flanged adapter too.

Below is a flanged adapter:

P.S. Sorry for the MS Paint spelling error. I do actually know how to spell straight...

Hope the photo helps show how a flanged adapter works.

__________________

- Alan Holman

- Posts: 62

- Joined: Sep 27th, '09, 13:42

- Location: As of 10/11/09 the proud new owner of Solo Noi(renaming scheduled for summer 2010)

Seacocks

I know it been said here before, but it bears repeating -- this is a fantastic board, with many helpful and knowledgeable contributors. In less than 24 hours I had a ton of information on how to chose the right seacocks for my boat. My thanks to everyone who responded. Now I have to make up my mind and I'll have to do that on my own. Oh, woe is me, a decision to make.

By the way, anyone know anything about Discount Marine Supplies out of Hersey, Penn.?

Thank again for all the help,

The Meddler

By the way, anyone know anything about Discount Marine Supplies out of Hersey, Penn.?

Thank again for all the help,

The Meddler

Sometimes your vessel's becalmed for days and weeks on end,

Sometimes the winds of life will blow you off your course, my friend,

But the wind is sure to veer, you must stay aboard and steer,

And long may your big jib draw!

Sometimes the winds of life will blow you off your course, my friend,

But the wind is sure to veer, you must stay aboard and steer,

And long may your big jib draw!

-

Troy Scott

- Posts: 1470

- Joined: Jan 21st, '06, 01:23

- Location: Cape Dory 36 IMAGINE Laurel, Mississippi

seacock experience

Mr. Meddler,

Here is my recent experience:

I am doing a big refit on a CD36. When this boat came into my life, she had an odd mix of old stuck Spartan seacocks, through-hulls with Apollo ball valves added to them (mis-matched threads, of course), and some Apollo flanged seacocks. They were all stuck and in need of replacement or thorough cleaning and service. I wanted to bring my CD36 back to her original, all-Spartan seacocks status, but the cost was ridiculous. I decided to order matched bronze Apollo flanged seacocks for the whole boat, with new mushroom fittings and hose adapters. When the Apollo flanged seacocks arrived, I was SERIOUSLY disappointed. Their appearance was really rough, and the valves were so tight that I had to clamp the flanges to a work table and use a cheater bar to even get the handles to move. I decided I couldn't live with a boat full of those. After consulting with the folks at Groco, I ordered a 1 1/2" Groco flanged seacock (the better BV series, not the cheaper FBV series) to see if it would be any better than the Apollo units. There is no comparison. The Groco valve is silky smooth and not difficult to operate, and it looks much better. I returned the whole Apollo mess and reordered in Groco. They are definitely worth the extra cost, and they are still a lot cheaper than Spartan.

Another important part of my new seacock system: I eliminated the old plywood backing plates. They were in terrible condition, and they matched the Spartan bases, which are very different compared to the new flanged seacock bases. I made new 1/2" thick fiberglass backing plates. I carefully trimmed and shimmed to make sure each new flange base (backing plate) is properly aligned to the hull. The new bases are structurally bonded to the hull. I made several jigs, one for each size valve, to help me drill the bolt holes perfectly. I drilled the holes from the inside. I cut the countersinks from the outside. I want to point out here that several brands of the triangular based flanged seacocks are interchangeable because of their shared bolt patterns.

I investigated the Groco flanged base, but I didn't want to use the FBV valves that fit them. The valve in the BV series seems better to me. There are probably situations where the flanged base is the best option. I don't have any of those situations.

I plan to service and sell the several intact Spartan seacocks that are worth salvaging.

Here is my recent experience:

I am doing a big refit on a CD36. When this boat came into my life, she had an odd mix of old stuck Spartan seacocks, through-hulls with Apollo ball valves added to them (mis-matched threads, of course), and some Apollo flanged seacocks. They were all stuck and in need of replacement or thorough cleaning and service. I wanted to bring my CD36 back to her original, all-Spartan seacocks status, but the cost was ridiculous. I decided to order matched bronze Apollo flanged seacocks for the whole boat, with new mushroom fittings and hose adapters. When the Apollo flanged seacocks arrived, I was SERIOUSLY disappointed. Their appearance was really rough, and the valves were so tight that I had to clamp the flanges to a work table and use a cheater bar to even get the handles to move. I decided I couldn't live with a boat full of those. After consulting with the folks at Groco, I ordered a 1 1/2" Groco flanged seacock (the better BV series, not the cheaper FBV series) to see if it would be any better than the Apollo units. There is no comparison. The Groco valve is silky smooth and not difficult to operate, and it looks much better. I returned the whole Apollo mess and reordered in Groco. They are definitely worth the extra cost, and they are still a lot cheaper than Spartan.

Another important part of my new seacock system: I eliminated the old plywood backing plates. They were in terrible condition, and they matched the Spartan bases, which are very different compared to the new flanged seacock bases. I made new 1/2" thick fiberglass backing plates. I carefully trimmed and shimmed to make sure each new flange base (backing plate) is properly aligned to the hull. The new bases are structurally bonded to the hull. I made several jigs, one for each size valve, to help me drill the bolt holes perfectly. I drilled the holes from the inside. I cut the countersinks from the outside. I want to point out here that several brands of the triangular based flanged seacocks are interchangeable because of their shared bolt patterns.

I investigated the Groco flanged base, but I didn't want to use the FBV valves that fit them. The valve in the BV series seems better to me. There are probably situations where the flanged base is the best option. I don't have any of those situations.

I plan to service and sell the several intact Spartan seacocks that are worth salvaging.

Regards,

Troy Scott

Troy Scott

-

Maine Sail

- Posts: 839

- Joined: Feb 8th, '06, 18:30

- Location: Canadian Sailcraft 36T

Re: seacock experience

Troy,Troy Scott wrote: I investigated the Groco flanged base, but I didn't want to use the FBV valves that fit them. The valve in the BV series seems better to me. There are probably situations where the flanged base is the best option. I don't have any of those situations.

For future reference this is a 7-8 year old FBV all the Groco stuff is pretty reliable..

Last edited by Maine Sail on Dec 1st, '09, 15:12, edited 1 time in total.

-

Troy Scott

- Posts: 1470

- Joined: Jan 21st, '06, 01:23

- Location: Cape Dory 36 IMAGINE Laurel, Mississippi

Maine Sail,

I'm very happy to see that FBV valve looking so good after seven or eight years. I believe they are probably better than the Apollo valves. My decision to use the Groco BV valves was based on my research and my discussions with the engineers at Groco. As I wrote, the Groco flanged base combined with an inline ball valve is probably the best solution in some cases. It's just not what I chose to do.

sharkbait,

I certainly agree that the threads should match. Tapping is a reasonable way to make that happen. If you are using these re-tapped inline valves as seacocks, I hope you are installing them on sturdy flanged through-hull fittings. Valves installed directly on through-hull fittings are not secure if the through-hull has only a nut holding it to the hull. A good, sturdy bolted-on flange needs to handle the loads imposed on the through-hull by the valves and plumbing. Also, a correctly made and installed flanged seacock base will not allow seawater into the boat even if the through hull is missing. This is important especially if the boat is involved in an unfortunate incident that causes the mushroom head of the through hull to be ground or knocked off.

I'm very happy to see that FBV valve looking so good after seven or eight years. I believe they are probably better than the Apollo valves. My decision to use the Groco BV valves was based on my research and my discussions with the engineers at Groco. As I wrote, the Groco flanged base combined with an inline ball valve is probably the best solution in some cases. It's just not what I chose to do.

sharkbait,

I certainly agree that the threads should match. Tapping is a reasonable way to make that happen. If you are using these re-tapped inline valves as seacocks, I hope you are installing them on sturdy flanged through-hull fittings. Valves installed directly on through-hull fittings are not secure if the through-hull has only a nut holding it to the hull. A good, sturdy bolted-on flange needs to handle the loads imposed on the through-hull by the valves and plumbing. Also, a correctly made and installed flanged seacock base will not allow seawater into the boat even if the through hull is missing. This is important especially if the boat is involved in an unfortunate incident that causes the mushroom head of the through hull to be ground or knocked off.

Regards,

Troy Scott

Troy Scott

-

Maine Sail

- Posts: 839

- Joined: Feb 8th, '06, 18:30

- Location: Canadian Sailcraft 36T

NPT to NPT is a pressure fit. This means that it is a sealing thread designed to withstand high pressures and also one that "tightens".sharkbait wrote:Just to add a twist to the whole issue. I have used NPS taps to change one end of the ball valves from NPT to NPS. You have to dis-assemble the valve run the tap and then reassemble. But, it works if the situation requires.

NPS to NPS in the scenario of a BV to a thru-hull should certainly be treated with much caution. Because NPS/NPS is not a "sealing" thread nor one that tightens, unless you bottom out the valve onto the thru-hull, it can be dangerous both in terms of leaks and the ability for the valve to work it's way free if allowed to.

Nuts and bolts are straight thread and thus require lock washers or nylock nuts. Ball valves do not have lock washers. One other issue is potential damage to the phenolic seat in the valve by over tightening the valve onto the NPS thru hull. Some valves do not have a butt ring inside the valve to protect the phenolic valve seat. If tapping a BV with a butt seat, as seen in the photo in the above post, you can hit this and could potentially tap right through it. On valves with butt seats these are what help to hold the phenolic seat into the valve body.

Tapping an NPT valve to NPS could be potentially dangerous..

-

Tom in Cambria

- Posts: 120

- Joined: Jan 29th, '06, 22:39

- Location: Cape Dory 31

Full Flow seacocks and valves

Unless I missed it no one explained what a "full flow" valve is. If you're working with an inch and a half valve or seacock full flow means that when the valve is open the opening is a full inch and a half all the way through. Some valves which accept 1.5 inch hoses have smaller interior passages so that the flow is actually only an inch or less. You can see this in the second picture where the outside dimension is much larger that the actual bore in the ball. If you're going to put a 1.5 inch hole in your boat for the seacock you want the full advantage of that size hole, which means a full flow valve.

I guess you all know that "NPT" stands for "national pipe thread". Threads on a pipe are tapered so that as you screw a fitting on a pipe it gets tighter as you screw. On iron pipe you must put pipe dope or teflon tape on the threads or they will rust together over time and be impossible to remove. Bronze pipe doesn't rust, but people often put teflon tape on them as well just to make them easier to unscrew if it ever become necessary. There is an agreed upon degree of taper and number of threads per inch and that's why it's a "national" pipe thread, i.e., it meets the national standard.

I guess you all know that "NPT" stands for "national pipe thread". Threads on a pipe are tapered so that as you screw a fitting on a pipe it gets tighter as you screw. On iron pipe you must put pipe dope or teflon tape on the threads or they will rust together over time and be impossible to remove. Bronze pipe doesn't rust, but people often put teflon tape on them as well just to make them easier to unscrew if it ever become necessary. There is an agreed upon degree of taper and number of threads per inch and that's why it's a "national" pipe thread, i.e., it meets the national standard.

-

Oswego John

- Posts: 3535

- Joined: Feb 5th, '05, 20:42

- Location: '66 Typhoon "Grace", Hull # 42, Schooner "Ontario", CD 85D Hull #1

Deja Vu All Over Again

Hi Tom and all,

This is a fantastic coincidence for me. I'm speaking in relation to Tom In Cambria's recent post. After reading through the board contents today, I made a mental note to write either a PM or a general post including a concern for Tom. Tom and I hear from each other maybe once or twice in a couple of years. Tonight is a "must write" occasion. Heres is why.

It had to be all of six or seven years ago that Tom wrote in and asked me or anyone a question concerning how to negotiate the change in thread types when installing a sea cock.

I should have simply said "I don't Know, sorry". But no, I gave an outlandish, Mickey Mouse, Rube Goldbergesque definition of procedure that included jam nuts to ensure the stupid thing didn't fall apart.

Today, when I read up on and saw Main Sail's picture of a flanged adapter, it all came back to me. Of course, that is the proper way to transfer from one type of thread system to the other. But I believe that Tom also saw Main Sail's presentation.

BTW, I should mention that Tom in Cambria is quite an accomplished writer, also. I don't mean to embarrass him by relating how he sent me a wonderful copy of a detailed daily ship's log while cruising and island hopping in the Bahamas. It was very interesting to read of his activities, including details and nuances not commonly found in a personal log. It was a great read.

On another tack, I prefer to use teflon paste on threads rather than tape. The tape tends to bunch up after a few threads and doesn't protect the entire thread. The paste covers all the hills and valleys of the thread and stays where it was applied. It doesn't completely harden

The best pipe dope I think is pipe fitters black, paint on, paste dope. Warning. When working with black dope, wear your oldest ratty clothes. This devilish thread seal has a propensity to leap at least three feet through the air from the work to the nearest garment in the area. It doesn't wash out. It's there for life (but so is the joint it protects). How good is it? It is one of the few that are approved by the AEC, NRC. So that not only makes it airtight and bullet proof, but also nuclear proof. So I guess it will stand up to the rigid CD quality control specs.

Happy schmearing,

O J

This is a fantastic coincidence for me. I'm speaking in relation to Tom In Cambria's recent post. After reading through the board contents today, I made a mental note to write either a PM or a general post including a concern for Tom. Tom and I hear from each other maybe once or twice in a couple of years. Tonight is a "must write" occasion. Heres is why.

It had to be all of six or seven years ago that Tom wrote in and asked me or anyone a question concerning how to negotiate the change in thread types when installing a sea cock.

I should have simply said "I don't Know, sorry". But no, I gave an outlandish, Mickey Mouse, Rube Goldbergesque definition of procedure that included jam nuts to ensure the stupid thing didn't fall apart.

Today, when I read up on and saw Main Sail's picture of a flanged adapter, it all came back to me. Of course, that is the proper way to transfer from one type of thread system to the other. But I believe that Tom also saw Main Sail's presentation.

BTW, I should mention that Tom in Cambria is quite an accomplished writer, also. I don't mean to embarrass him by relating how he sent me a wonderful copy of a detailed daily ship's log while cruising and island hopping in the Bahamas. It was very interesting to read of his activities, including details and nuances not commonly found in a personal log. It was a great read.

On another tack, I prefer to use teflon paste on threads rather than tape. The tape tends to bunch up after a few threads and doesn't protect the entire thread. The paste covers all the hills and valleys of the thread and stays where it was applied. It doesn't completely harden

The best pipe dope I think is pipe fitters black, paint on, paste dope. Warning. When working with black dope, wear your oldest ratty clothes. This devilish thread seal has a propensity to leap at least three feet through the air from the work to the nearest garment in the area. It doesn't wash out. It's there for life (but so is the joint it protects). How good is it? It is one of the few that are approved by the AEC, NRC. So that not only makes it airtight and bullet proof, but also nuclear proof. So I guess it will stand up to the rigid CD quality control specs.

Happy schmearing,

O J

"If I rest, I rust"

Voting Member #490

Voting Member #490